💡 Introduction

As the demand for longer range and safer energy storage grows, semi-solid-state batteries have become a key innovation in the lithium battery industry. By combining the benefits of both solid and liquid electrolytes, semi-solid cells provide a balance between energy density, safety, and manufacturability.

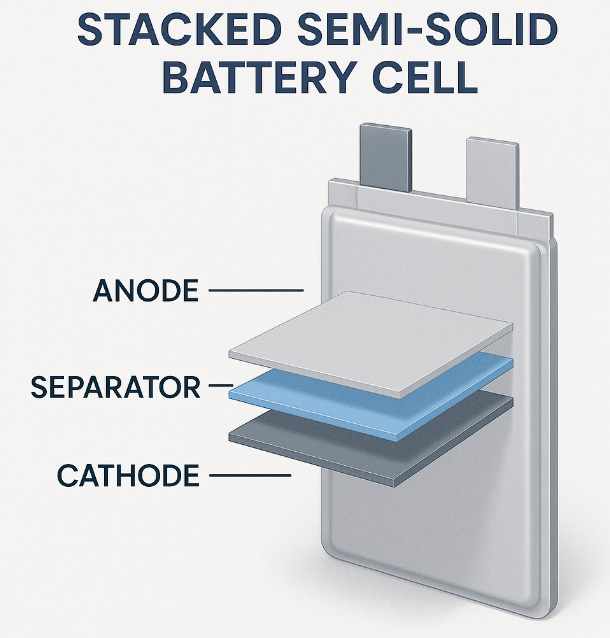

Among various production methods, the stacking process — rather than traditional winding — has emerged as the optimal choice for achieving high-performance, large-format semi-solid lithium cells. This approach allows for greater precision and consistency in electrode alignment, resulting in improved efficiency and long-term stability.

📈 Market Trend & Technical Requirements

The global transition to electrification — particularly in electric vehicles (EVs), energy storage systems (ESS), and aerial mobility — demands batteries that offer both high energy density and superior thermal stability.

- 🔋 20–40% higher volumetric energy density compared to liquid-electrolyte systems

- 🛡️ Reduced leakage and fire risk due to semi-solid electrolytes

- ⚙️ Ideal for large-capacity applications (100Ah–300Ah per cell)

- 🌡️ Stable heat dissipation and uniform structural strength

These batteries are widely adopted in EVs, ESS containers, and high-temperature environments that require both safety and performance reliability.

⚙️ Typical Battery Configuration

- Nominal Voltage: 3.7V–4.2V

- Capacity Range: 50Ah–300Ah

- Chemistry: High-nickel NCM811 or NCA, lithium-rich or silicon-doped anodes

- Electrolyte: Semi-solid polymer or gel composite

- Format: Pouch or prismatic stacked design

This architecture ensures each layer maintains uniform pressure, minimizing mechanical stress and ensuring consistent ion transport across electrodes — key for both LiFePO₄ and high-nickel systems.

🔬 Performance Comparison & Engineering Insight

Compared with the traditional winding process, stacking offers multiple advantages for lithium-ion battery production:

- ⚡ Higher Energy Utilization: Maximizes active material loading and minimizes dead space.

- 🔋 Lower Internal Resistance: Improves power output and efficiency.

- 🌡️ Better Thermal Management: Uniform layer distribution enhances heat dissipation.

- 🧱 Improved Structural Integrity: Reduced risk of short circuits and delamination.

When paired with high-nickel or Li-rich materials, stacked semi-solid cells can achieve energy densities above 350 Wh/kg — significantly higher than traditional liquid-based systems (typically 250–280 Wh/kg).

🏭 PKNERGY Custom Semi-Solid Battery Solutions

PKNERGY specializes in custom semi-solid and high-energy-density lithium battery packs, leveraging:

- Precise cell matching and semi-solid stacking technology

- Advanced BMS design with CAN / RS485 communication

- IP67-rated enclosure design and modular integration

- Prototype development and certification: UN38.3 / IEC62133 / CE / UL

Our R&D team continuously innovates in semi-solid interface technology and stacking automation, helping OEMs achieve longer range, higher efficiency, and superior safety in EVs, ESS, and aerospace applications.

📩 Contact PKNERGY

Looking for advanced semi-solid battery solutions for your next-generation product? Contact PKNERGY today to discuss your custom design and OEM/ODM needs.

📞 Direct Contact Information

Email: sale@pknergy.com

WhatsApp: +86 13902463897

Website: www.pknergybattery.com