|

Custom Lithium Battery • Alarm Systems

Rechargeable Lithium Battery for Power Outage Alarm Devices

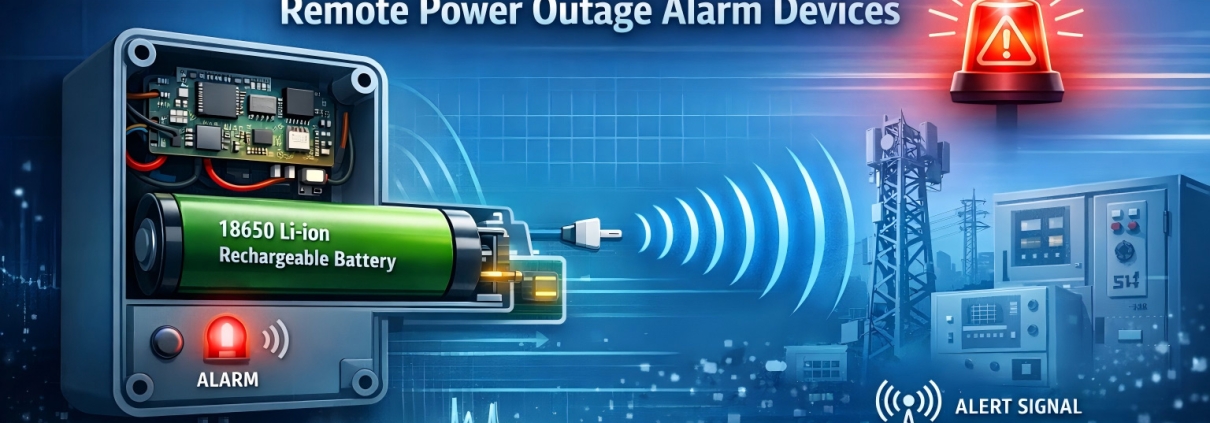

A reliable rechargeable lithium battery designed for power outage alarm devices, ensuring stable backup power, immediate alarm transmission, and long-term unattended operation.

Rechargeable 18650 Li-ion battery solution for remote power outage alarm devices. Stable backup power, low maintenance, and high reliability for unattended monitoring systems.

|

Application photo: power outage alarm device for unattended monitoring.

|

Project Snapshot

- Application: Power outage alarm & monitoring devices

- Power Architecture: AC mains + rechargeable lithium battery backup

- Battery Function: Ensures alarm transmission during power loss

- Customization Focus: Long standby life, safety, and stable output

Rechargeable Lithium Battery Pack

Battery photo: 18650-based rechargeable lithium battery pack.

Application Background

Power outage alarm devices are commonly used in electrical infrastructure, telecom rooms, smart buildings, and industrial facilities. These systems rely on a backup battery to guarantee that alarms and notifications are transmitted immediately when mains power is lost.

Battery Requirements for Alarm Devices

- Long standby life with minimal self-discharge

- Stable voltage output during alarm transmission

- High safety for unattended installation

- Rechargeable design for low maintenance

- Compatibility with compact enclosures

PKNERGY Rechargeable Battery Solution

PKNERGY provides custom rechargeable lithium battery packs tailored for alarm devices, combining controlled charging, optimized protection circuits, and reliable 18650 cells to support long-term standby and instant alarm response.

Reference Battery Parameters

| Item |

Specification |

| Cell Type |

18650 Rechargeable Lithium Cell |

| Nominal Voltage |

3.7 V |

| Typical Capacity |

2600 mAh (customizable) |

| Charge Voltage |

4.2 V |

| Cycle Life |

≥500 cycles @ 80% DOD |

FAQs

Why is a rechargeable battery preferred for power outage alarms?

Rechargeable batteries allow automatic replenishment during normal operation, reducing maintenance and ensuring readiness during outages.

Can the battery be customized for different alarm devices?

Yes. Capacity, size, connector, and protection strategy can all be customized.

Is the battery safe for unattended installation?

Yes. Multi-level protection ensures safe long-term operation.

Contact Miah — PKNERGY

Need a custom lithium battery for alarm or monitoring systems?

Contact us

to discuss your project.

Email: sale@pknergy.com