Custom Lithium Battery Solutions for Hull Cleaning Robots

Reliable Power for Marine Maintenance and Underwater Robotics

1. Introduction

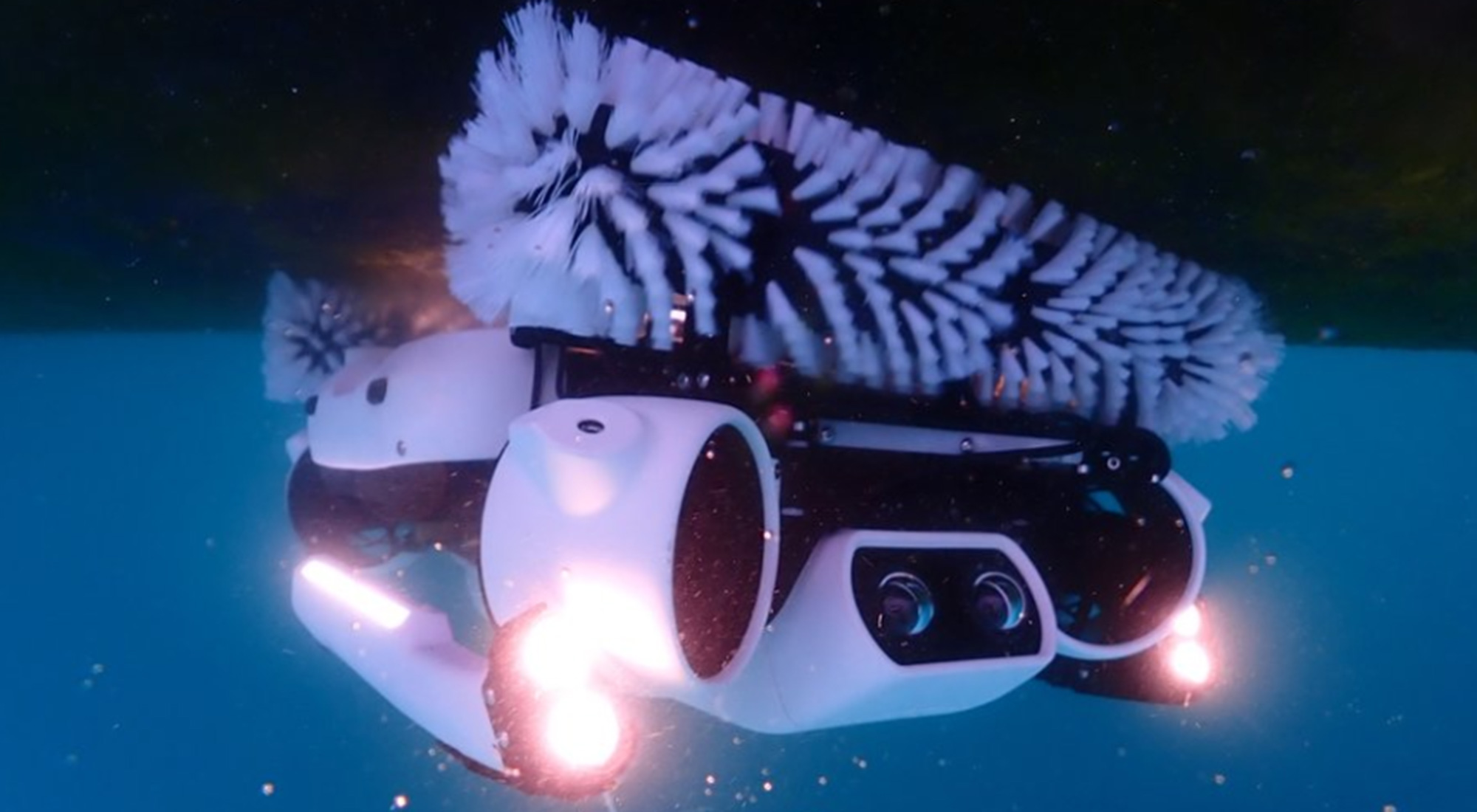

Hull cleaning robots are essential tools for maintaining ship efficiency and reducing fuel consumption. These underwater or semi-submerged robots rely on high-performance lithium battery systems to operate in harsh marine environments. Any battery failure can result in downtime and costly maintenance interruptions.

PKNERGY provides advanced custom lithium battery solutions designed for marine robotics — combining high energy density, waterproof protection, and reliable long-term performance.

2. Key Battery Requirements for Hull Cleaning Robots

- Long Runtime and High Capacity: Extended operation per charge (6–12 hours typical).

- Safety and Waterproof Design: IP67+ sealed housing to prevent saltwater intrusion.

- Compact and Lightweight: Space-efficient design without sacrificing performance.

- Temperature Resistance: Reliable function in –10°C to +60°C marine conditions.

- Certifications: UN38.3, IEC62133, CE, MSDS for global compliance.

3. Challenges in Marine Robotics Power

Continuous Operation in Remote Areas

Hull cleaning robots often operate autonomously without immediate shore power access.

PKNERGY Solution: High-capacity Li-ion and LiFePO₄ batteries with rapid recharge and low self-discharge.

Exposure to Saltwater and Corrosive Conditions

Marine environments accelerate corrosion and oxidation.

Solution: Waterproof IP67–IP68 housing with anti-corrosion coatings.

Space and Weight Limitations

Compact robotic hulls require lightweight energy systems.

Solution: Custom-designed battery geometries maximizing energy density per volume.

4. PKNERGY’s Custom Battery Solutions

PKNERGY ENERGY develops and produces custom battery packs engineered for hull cleaning robots and underwater equipment.

- High-performance Li-ion / LiFePO₄ packs with BMS integration

- Voltage range: 14.4V–25.6V; capacity: 5Ah–20Ah

- Waterproof sealing with IP67/IP68 protection

- Lightweight composite or aluminum casing for heat dissipation

- Long cycle life: 2000+ cycles at 80% DOD

Example: 21.6V 6000mAh LiFePO₄ pack with integrated BMS and waterproof casing — delivering 16–36 hours of continuous operation and over 2000 life cycles.

5. Case Study

Client: European marine maintenance company

Requirement: Long-lasting waterproof power solution for robotic hull cleaning systems.

Solution: Custom 4S2P 12.8V 8Ah LiFePO₄ battery with marine-grade BMS and IP67 aluminum casing.

Result: Reliable 5–6 hours of continuous underwater operation with stable voltage output and minimal maintenance.

6. Collaboration Process with PKNERGY

- Requirement Analysis

- Custom Solution Design

- Prototype & Testing

- Validation & Certification

- Mass Production & Delivery

Why PKNERGY:

- 26 years of lithium battery design and manufacturing experience

- Proven record in marine, industrial, and robotics sectors

- OEM/ODM flexibility and complete certification support

7. FAQ

What is the typical MOQ for marine battery packs?

Usually 50–5000 pcs depending on specification and customization level.

How long is the lead time?

Sample delivery in 25 days; mass production in 45–60 days.

Are PKNERGY batteries suitable for saltwater environments?

Yes. All marine packs are sealed with IP67/IP68 waterproof housings and anti-corrosion coatings.

8. Contact Jennifer — PKNERGY

Email: sale3@pknergy.com

Tel / WhatsApp / WeChat: +86 13823598934

PKNERGY provides custom lithium battery solutions for marine robots, underwater drones, and hull cleaning systems worldwide.