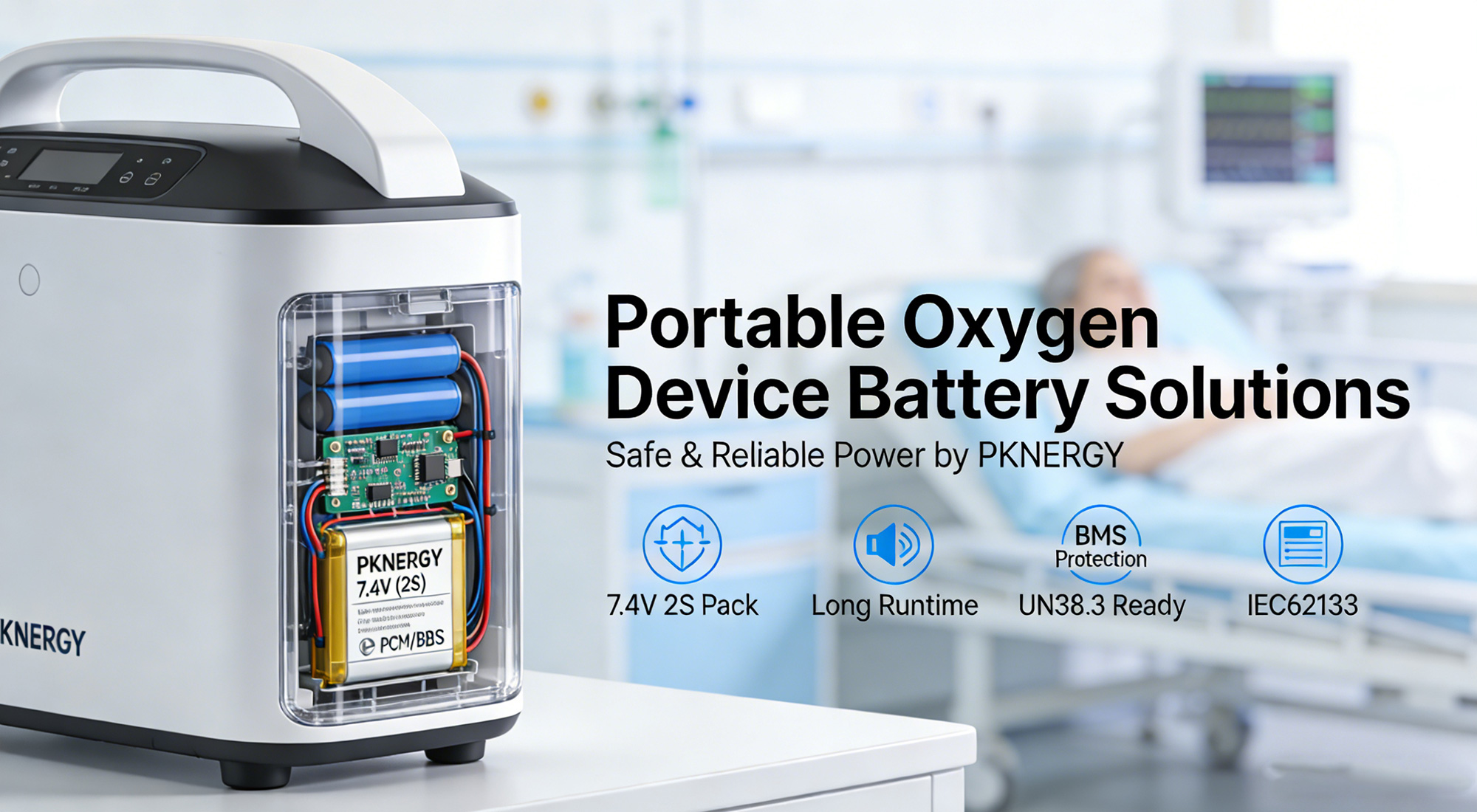

Custom Lithium Battery Solutions for Portable Oxygen Devices

Compact, Rechargeable, and Reliable Power for Respiratory Care Equipment

Medical Battery

Portable Oxygen

Custom Li-ion Pack

Overview

Portable oxygen devices and respiratory care equipment depend on power systems that are compact, rechargeable, and reliable.

For end users, stable runtime is directly linked to comfort and safety. For manufacturers, battery selection affects

product performance, compliance, and total lifecycle cost.

Lithium battery technology has become a preferred solution for portable oxygen concentrators and related devices,

thanks to its high energy density, stable voltage output, and extended cycle life.

Why Lithium Batteries for Portable Oxygen Devices?

Compared with traditional chemistries, lithium batteries can deliver longer runtime at the same weight and size,

which is critical for truly portable medical products. Rechargeable lithium batteries also support daily use cycles

without frequent replacement, reducing long-term maintenance cost.

For compact housings and medical-grade integration, PKNERGY supports

custom lithium battery designs and

custom lithium polymer batteries

for space-optimized structures.

Typical Pack Configurations for Portable Oxygen Concentrators

Many portable oxygen devices use 2S lithium-ion battery packs (7.4V nominal) or higher configurations,

commonly in the range of 2000mAh to 4000mAh, depending on power consumption and target runtime.

| Typical Configuration | Nominal Voltage | Common Capacity Range | Design Notes |

|---|---|---|---|

| 2S (Series) | 7.4V | 2000–4000mAh | Common for compact portable oxygen devices; good balance of size and runtime |

| Higher Configurations | 7.4V+ | Depends on device | For higher power draw, longer runtime, or specific charging system requirements |

Need longer endurance or improved stability? You can also evaluate

custom LiFePO4 battery packs

based on your system voltage and enclosure constraints.

Safety & Protection Design for Medical Devices

For medical and respiratory equipment, safety is non-negotiable. R&D engineers typically prioritize protection features such as:

- Overcharge protection to avoid abnormal cell stress

- Over-discharge protection to prevent capacity damage and unsafe conditions

- Overcurrent / short-circuit protection for robust device operation

- Thermal protection for stability during continuous running

A well-designed protection solution (PCM/BMS) helps ensure reliable performance under real-world usage patterns,

including continuous operation and repeated charge/discharge cycles.

Procurement Checklist (Compliance + Supply Reliability)

Procurement managers should evaluate both product performance and the supplier’s compliance capability.

For international shipping and medical-related projects, common considerations include:

- UN38.3 readiness for lithium battery transportation

- IEC62133 (or related) safety compliance alignment depending on target markets

- Consistency of cells and pack assembly for stable mass production

- Engineering support for pack customization, harness/connector, and mechanical integration

For more medical device power solutions, you may also reference:

Medical Device Power Solution.

Why PKNERGY for Portable Oxygen Device Batteries

Custom Pack Engineering

Voltage, capacity, and structure customization to match your oxygen device enclosure and runtime targets.

Safety-First Design

Protection strategy support (PCM/BMS) with practical testing considerations for continuous operation.

Compliance Support

International logistics and compliance alignment support for UN38.3 and medical-related requirements.

From Prototype to Mass Production

Fast sampling and scalable production capability to support healthcare brands and OEM projects.

If you want a fast evaluation, please prepare: target voltage, capacity, device power consumption,

operating temperature, enclosure space, and connector type.

FAQ

What voltage battery pack is commonly used in portable oxygen concentrators?

Many portable oxygen devices use 2S lithium-ion packs with 7.4V nominal voltage. The final configuration depends on

the device’s power draw, boost/drive circuit design, and charging system.

What capacity range is typical for portable oxygen device batteries?

Common designs range from about 2000mAh to 4000mAh, but the best choice depends on runtime targets and the device’s actual

operating current profile (continuous mode vs pulse mode, fan load, etc.).

Which certifications matter for shipping and medical compliance?

UN38.3 is commonly required for transportation. For medical device-related safety, many projects align with IEC62133 or related standards

depending on the market. Final certification depends on the complete end-product design and regulatory scope.

Can PKNERGY customize battery structure and connectors?

Yes. We support custom pack structure, harness, connectors, and integration optimization to fit your oxygen device enclosure and assembly workflow.