Lithium Battery Solutions for Multi-Sensor Fusion Mobile Chassis

Custom Li-ion & LiFePO₄ Battery Packs for AGV, AMR, and Robotics Platforms

Introduction

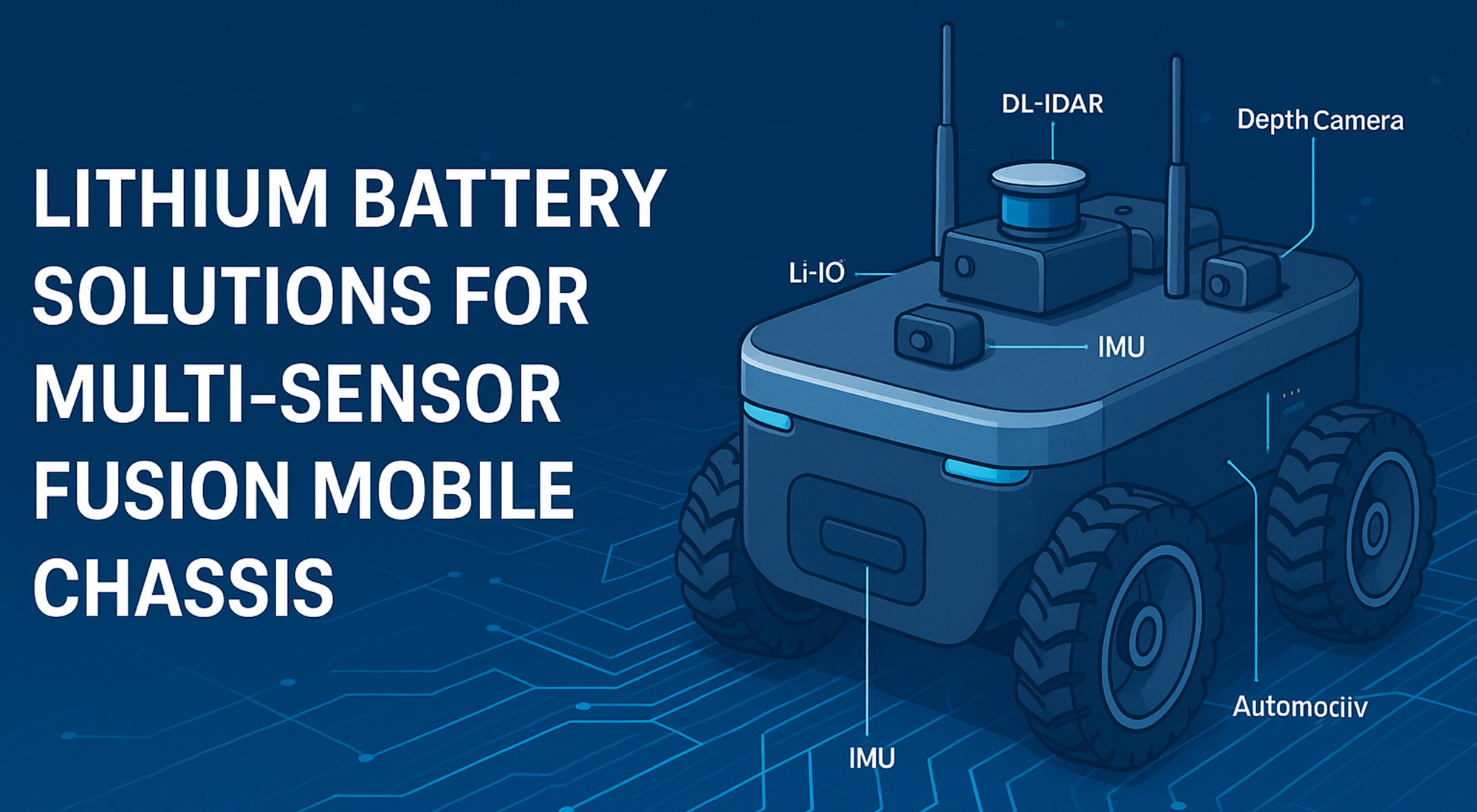

Multi-sensor fusion mobile chassis platforms are widely used in AGVs, AMRs, inspection robots, delivery robots, and autonomous mobile systems. These platforms integrate LiDAR, depth cameras, ultrasonic sensors, IMUs, motor drivers, and AI processors to achieve precise navigation and obstacle avoidance.

To ensure stable and efficient operation, these systems require a robust, long-lasting, and safe power source. PKNERGY provides custom LiFePO₄ battery and custom lithium polymer battery solutions engineered specifically for mobile chassis.

Application Background

A multi-sensor fusion mobile chassis demands continuous and reliable power to support multiple tasks simultaneously, including real-time mapping, navigation, motor control, and high-speed data processing. Core battery requirements include:

- Stable high-current output for motors and drive systems

- Consistent voltage for sensing & computing modules

- 8–16 hours runtime for daily deployment

- High cycle life for long-term use

- CANBus/RS485 monitoring

- Fast charging for operational efficiency

- Safe operation under vibration and heavy load

PKNERGY solves typical pain points such as voltage drops, overheating, and weak BMS integration with fully customized battery packs.

PKNERGY Battery Solutions for Mobile Chassis

✔ Chemistry Options

- Li-ion 18650/21700 – high energy density for lightweight robots

- LiFePO₄ – 2000+ cycles, high safety, ideal for AGV/AMR

- High-power Li-polymer – excellent discharge for dynamic robotics

✔ Electrical Specifications

- Voltage: 24V / 36V / 48V (custom)

- Capacity: 20Ah–100Ah+

- Discharge: 3C–5C continuous

- Low internal resistance for stable high-current output

✔ Smart BMS Features

- Overcharge/over-discharge protection

- Motor surge protection

- NTC temperature monitoring

- Cell balancing

- CANBus / RS485 / UART

✔ Structural Advantages

- Shock & vibration resistant design

- Waterproof IP54–IP67

- Custom connectors & harness

- Reliable A-grade cells

Explore more solutions:

AGV Power Solution |

Mobile Robot Battery |

Custom LiFePO₄ Battery

Value to Engineers & Project Managers

- Fast prototype sampling (10–15 days)

- Low MOQ for development projects

- OEM/ODM enclosure + BMS customization

- High consistency via automated production lines

- Complete testing: vibration, high-current, aging

Case Study: Industrial Mobile Chassis Manufacturer

A customer required a long-cycle battery system for a multi-sensor chassis with LiDAR, 3D cameras, ultrasonic sensors, and dual motors. PKNERGY delivered a 48V 40Ah LiFePO₄ pack with CANBus monitoring.

- 12–14 hours runtime

- Stable output under motor peaks

- Accurate SOC reporting

- 2500+ cycles, reduced replacement cost

Why PKNERGY

- 20+ years of custom lithium battery engineering

- Specialized in robotics, AGV & AMR battery packs

- Automated production & strict quality control

- Global export with full certifications

FAQ

What battery chemistry is best for AGVs and AMRs?

LiFePO₄ is recommended for industrial AGVs/AMRs due to its long cycle life, high safety, and stable output.

Can you integrate CANBus communication?

Yes. PKNERGY supports CANBus, RS485, UART, and other communication protocols.

Do you support custom enclosures?

Yes, including waterproof IP67 housings, metal cases, and custom molds.

Contact Cassie — PKNERGY

Email: sale4@pknergy.com

Tel/WhatsApp: +86 138 7460 4556

Website: www.pknergybattery.com