What Is the Most Expensive Part of a Lithium-Ion Battery?

Introduction

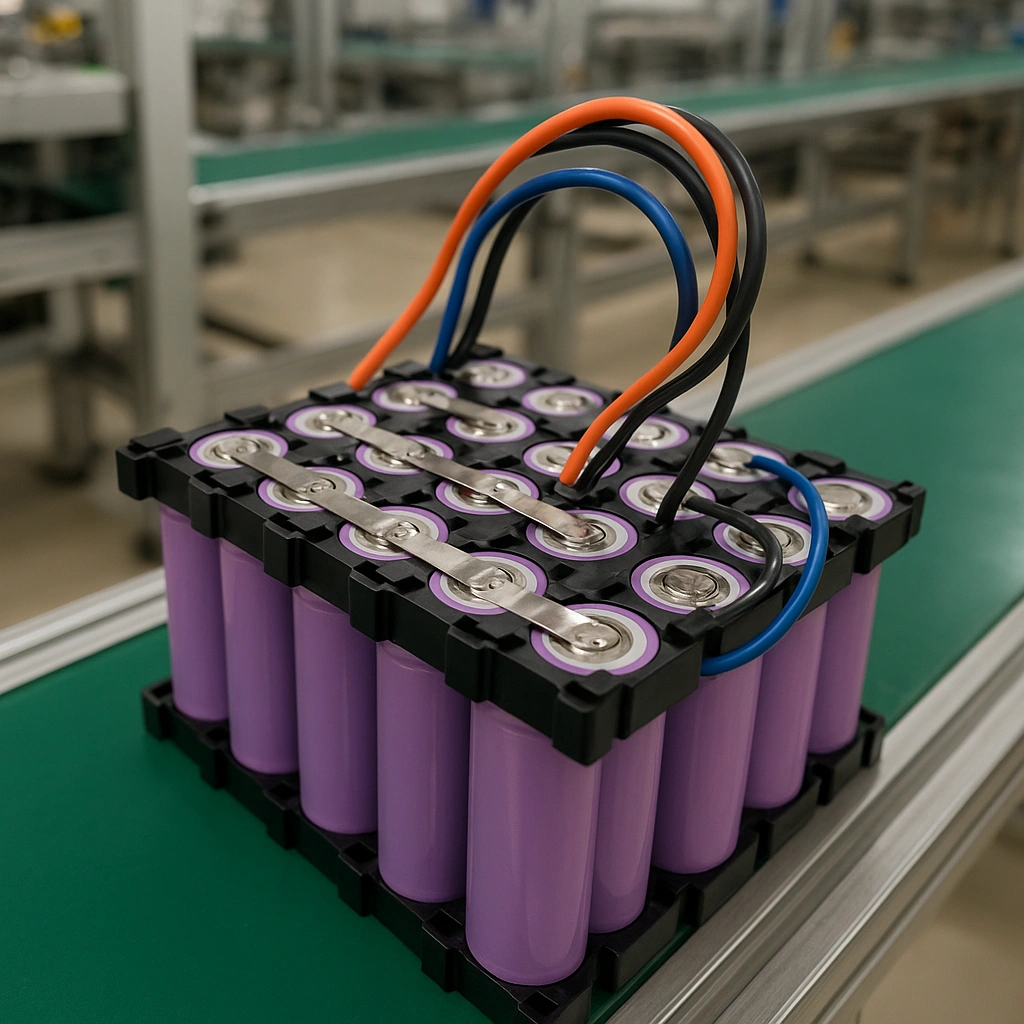

Lithium-ion batteries power everything from smartphones and laptops to electric vehicles and energy storage systems. While they are efficient and long-lasting, they are also relatively expensive to produce. But what exactly makes them so costly? Understanding the breakdown of lithium-ion battery costs reveals the materials and processes that drive pricing—and the opportunities for cost reduction and recycling.

What Are the Raw Materials for Lithium-Ion Batteries?

A typical lithium-ion battery is composed of several key materials:

-

Cathode: Often made of lithium cobalt oxide (LCO), lithium nickel manganese cobalt (NMC), or lithium iron phosphate (LFP)

-

Anode: Typically made of graphite

-

Electrolyte: Lithium salt dissolved in organic solvent

-

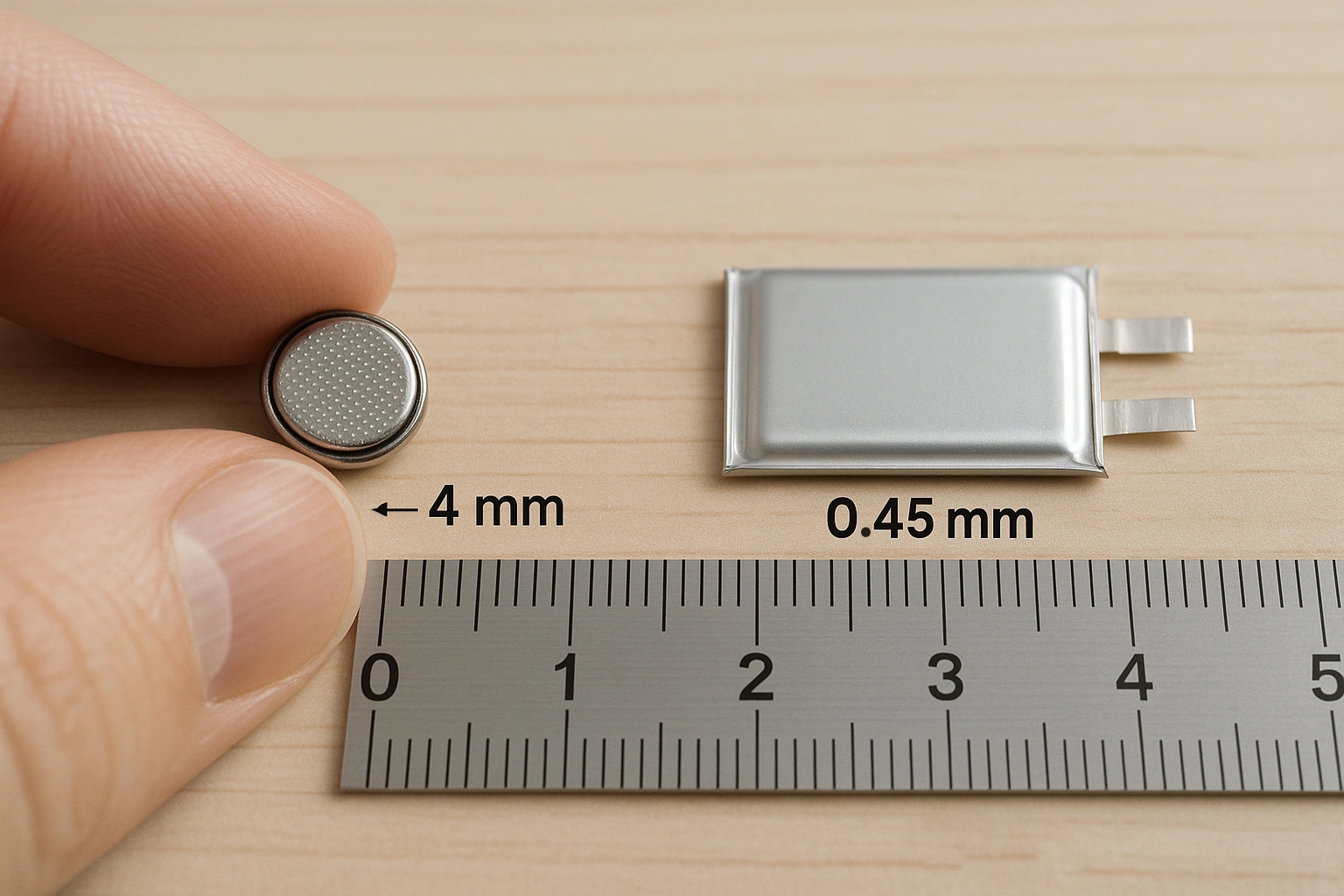

Separator: Thin membrane to prevent short circuits

-

Battery Management System (BMS): Electronics for monitoring and protection

Of these, the cathode material is the most critical in terms of cost and performance.

What Is Valuable in Batteries?

The value of a battery lies in:

-

High-purity lithium (Li)

-

Cobalt (Co) and nickel (Ni) in the cathode

-

Copper used in the current collectors

-

Battery-grade graphite in the anode

Among these, cobalt is the most valuable and price-volatile material, followed by nickel and lithium.

What Is the Most Expensive Part of a Lithium-Ion Battery?

The cathode accounts for 30–50% of the total battery cell cost, making it the single most expensive component.

In particular:

-

Cobalt-based cathodes (like NMC or NCA) are cost drivers due to cobalt’s high market price and supply risk.

-

Nickel is also increasingly used for higher energy density but adds cost and thermal management complexity.

In contrast, graphite (anode), separators, and electrolyte are less costly but still significant.

Is Cobalt More Expensive Than Lithium?

Yes. While lithium gets much attention, cobalt is historically more expensive per kilogram, often trading at 2–3 times the price of lithium carbonate.

-

Cobalt: Price fluctuations due to geopolitical concerns and ethical mining issues (e.g., DRC supply)

-

Lithium: High demand, but broader supply options (hard rock mining, brine extraction)

As demand grows, efforts to reduce or eliminate cobalt (e.g., LFP or cobalt-free cathodes) are accelerating.

Are Lithium Batteries More Expensive Than Lead-Acid?

Yes. Lithium-ion batteries cost more upfront due to:

-

Advanced materials (lithium, cobalt, nickel)

-

Built-in protection systems (BMS)

-

Higher manufacturing precision

However, they offer:

-

5–10x longer lifespan

-

Lighter weight

-

Higher depth of discharge and energy density

Total cost of ownership (TCO) is often lower over time compared to lead-acid.

Which Battery Is More Expensive?

| Battery Type | Relative Cost | Notes |

|---|---|---|

| NMC / NCA (Li-ion) | Highest | High energy density, contains cobalt and nickel, widely used in EVs and premium storage systems |

| LFP (LiFePO₄) | Moderate | Cobalt-free, cost-effective, excellent safety, common in solar and stationary storage |

| Sodium-ion | Lower | Emerging technology, competitive cost, suitable for low-temperature and stationary use |

| Lead-acid | Lowest | Low upfront cost, short lifespan, heavy, used in legacy systems and backup power |

· NMC and NCA batteries are the most expensive due to material cost

· LFP and sodium-ion batteries offer cost efficiency for many commercial and home energy systems

· Lead-acid is only suitable where cost is prioritized over performance

Is Lithium Recoverable from Batteries?

Yes. Lithium can be recovered from spent batteries using:

-

Hydrometallurgical processes

-

Pyrometallurgical methods

Recovery efficiency depends on battery type and process used. While lithium recovery rates can exceed 90%, it is still less economically attractive than recovering cobalt or nickel.

Can Lithium-Ion Batteries Be Recycled?

Absolutely. Most battery recycling targets:

-

Cobalt

-

Nickel

-

Copper

-

Graphite

-

Lithium (selectively, depending on economics)

Companies like Li-Cycle, Redwood Materials, and CATL are investing heavily in closed-loop recycling. Recycling reduces raw material dependency and supports environmental goals.

Is There Money in Recycling Lithium Batteries?

Yes — especially when cobalt or nickel is present. Recycling economics vary:

-

High-value batteries (NMC/NCA): Profitable due to cobalt/nickel resale

-

Low-value chemistries (LFP): Less recyclable revenue, but increasing due to regulations

Governments are introducing Extended Producer Responsibility (EPR) and incentives to make recycling viable even for lower-value batteries.

Conclusion

The most expensive part of a lithium-ion battery is its cathode, especially when it contains cobalt and nickel. As battery adoption accelerates across industries, controlling these material costs—and recycling them effectively—will be key to long-term sustainability.

Looking to reduce your battery cost or explore recyclable options? Contact PKNERGY for innovative lithium battery solutions with cobalt-free or recyclable chemistries.