What We Can Provide

Pknergy is a trusted expert in lithium battery customization. Our product lineup includes lithium-ion batteries, LiPo batteries, LiFePO4 batteries, sodium-ion batteries, and advanced packs tailored for diverse industries and high-demand applications.

We specialize in custom battery development—covering everything from concept to batch production. Pknergy delivers reliable, intelligent, and application-specific solutions with full engineering support and strict quality control.

Prototyping

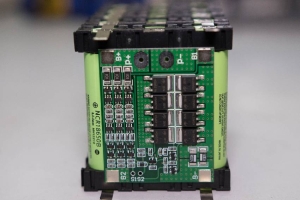

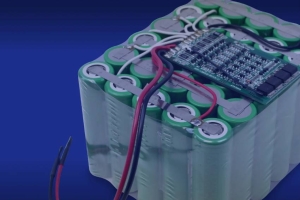

Pknergy provides custom lithium battery prototyping services, offering solutions that include cell selection, structural design, BMS integration, and manufacturing optimization tailored to your project requirements. We provide rapid prototyping with a focus on performance, compatibility, and safety, enabling you to expedite product development.

Software & BMS Solution

Pknergy’s intelligent BMS solutions offer real-time monitoring, SOC/SOH evaluation, and overcharge, overdischarge protection. With mobile app and web platform support, customers can remotely track battery status and optimize energy use, ensuring efficient operation and minimal downtime.

Mass Production & Quality Control

We utilize automated production lines, offering both small-batch prototyping and large-scale production. Our products undergo rigorous testing according to ISO quality standards and safety certifications (e.g., UN38.3, IEC62133, UL), guaranteeing long-term reliability while reducing maintenance costs.

Structural Design & Certification Support

Pknergy specializes in custom battery enclosures, modules, and thermal management solutions, designed to meet high safety standards and energy density requirements. Our solutions comply with UN38.3, UL, and IEC certification standards, ensuring that products meet regulatory requirements and industry safety standards.

Product Range

Lithium ion Battery Pack & CellLi Polymer Battery Pack & CellLiFePO4 Battery Pack & CellSodium-ion Battery CellSpecial Battery Pack & Cell

Lithium-ion Battery: High Energy Density for Versatile Applications

High Energy Density: Delivers longer usage time, suitable for a wide range of devices.

Lightweight: Reduces overall weight, ideal for portable devices and power tools.

High Efficiency: Supports fast charging with high discharge efficiency, enhancing device performance.

Versatile Applications: Widely used in consumer electronics, industrial equipment, and electric vehicles.

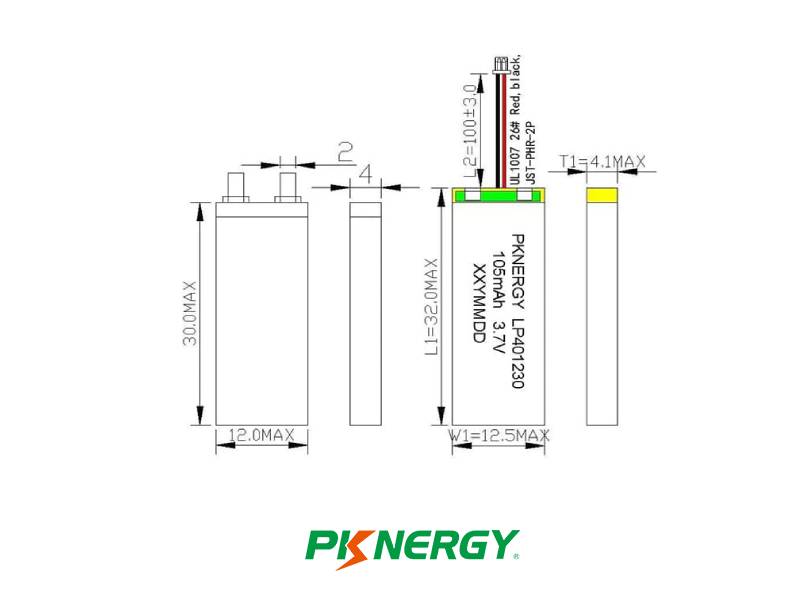

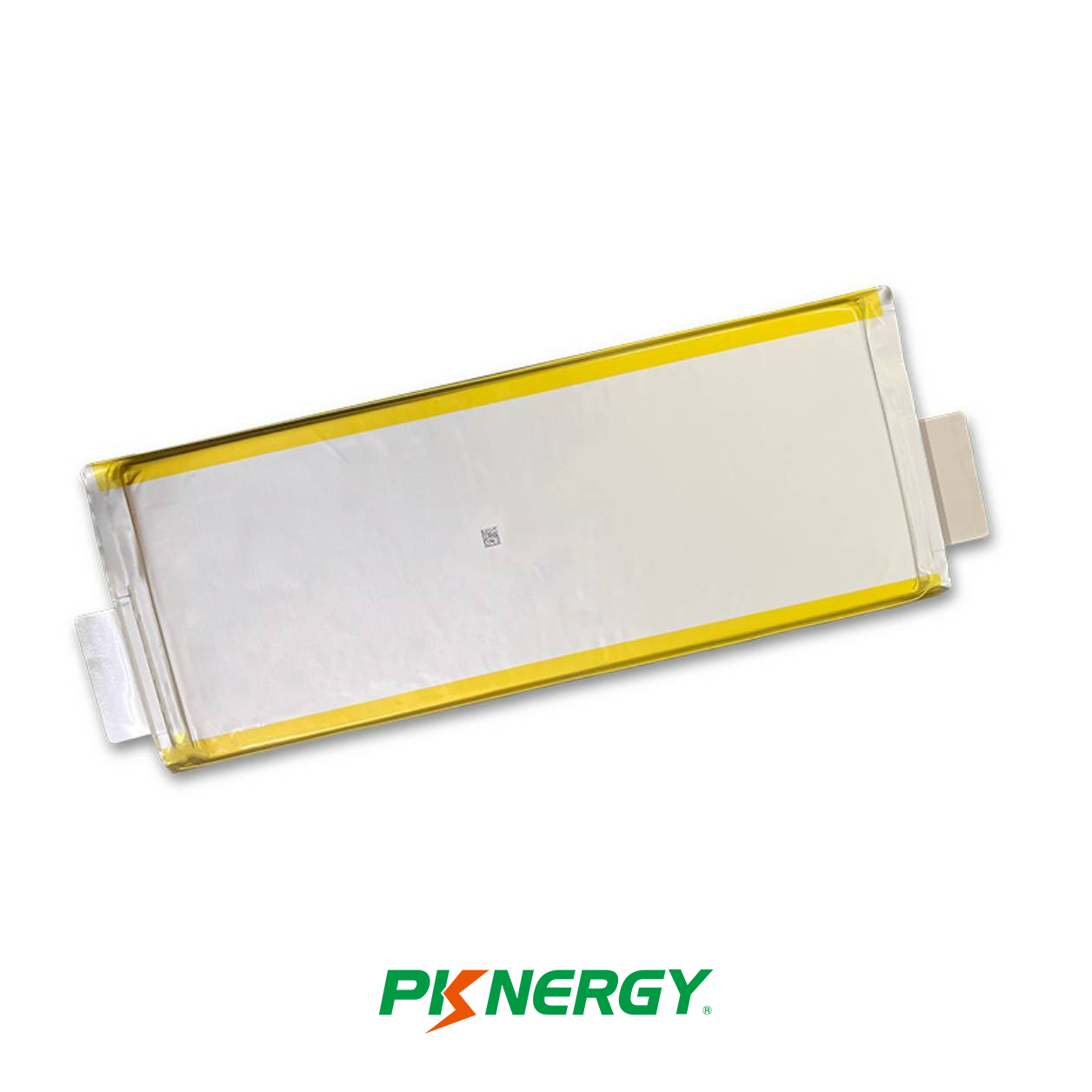

Li Polymer Battery: Lightweight and Flexible Power for Compact Devices

Ultra-thin Design: Flexible casing enables adaptable designs for various devices.

Enhanced Safety: Multi-layer protection structure minimizes risks of short circuits and overcharging.

High Discharge Rate: Delivers instant high-power output, suitable for drones and RC models.

Excellent Adaptability: Easily integrated into compact spaces, making them ideal for wearables and smart electronics.

LiFePO4 Battery Cell: Safe, Long-lasting Power for EVs and Storage

Ultra-long Cycle Life: Lifespan is several times longer than regular lithium-ion batteries, ideal for long-term use.

Higher Safety: Excellent thermal stability reduces risks of overheating, fire, or explosion.

Heat Resistance: Remains stable in high-temperature environments, perfect for outdoor energy storage and industrial applications.

Fast Charging and Discharging: Supports high current output, suitable for electric vehicles and energy storage systems.

Sodium-ion Battery Cell: Sustainable, Cost-effective Solution for Large-scale Energy

Outstanding Low-Temperature Performance: Maintains stable energy output in cold environments, suitable for extreme weather conditions.

Lower Material Cost: Compared to lithium batteries, sodium-ion batteries are more economical in terms of material cost.

Eco-friendly: Reduced use of rare metals in production contributes to better sustainability.

High Flexibility: Suitable for various scales of energy storage projects, particularly in energy reserves and large-scale grid storage.

Special Battery: Custom Solutions for Unique and Demanding Applications

Customizable Design: Tailored to meet specific application requirements across diverse industries.

Special Functionalities: High-rate, extreme temperature resistance, and ultra-thin design cater to demanding environments or specific projects.

Broad Application Range: Versatile use in military, aerospace, and medical equipment, demonstrating strong adaptability.

High Reliability: Ensures stable operation in critical mission applications.

-50°-80°C Wide-Temperature-Range Cylindrical Battery

-40°-60°C Wide-Temperature-Range Pouch Battery

-50°-60°C Wide-Temperature-Range Prismatic Battery

What Our Clients Are Saying About PKNERGY

We needed a reliable lithium-ion battery pack for our industrial monitoring device. Pknergy offered a custom solution that fit perfectly in size and voltage, with great cycle life. Since deployment, our device runs longer and more consistently. Their engineering team was very helpful throughout the process.

Our wearable medical device required an ultra-thin and lightweight power source. Pknergy’s custom lithium polymer battery pack exceeded our expectations. It offers stable output and fits our compact design perfectly. Their fast communication and technical knowledge made the project smooth and efficient.

Our equipment operates in sub-zero environments, and regular batteries failed frequently. Pknergy provided a custom low-temperature lithium battery pack that works reliably at -30°C. Since switching, downtime has been eliminated. Their technical support was excellent, and delivery was on time.

Steps to Custom Battery Process

Requirement Analysis

Initial Consultation: Discuss project needs with the client, including voltage, capacity, size, shape, temperature requirements, and application scenarios.

Feasibility Study: Evaluate the technical feasibility and initial design requirements based on the client’s specifications.

Feasibility Study: Evaluate the technical feasibility and initial design requirements based on the client’s specifications.

01

Solution Design

Preliminary Design Proposal: Develop an initial design that aligns with the client’s requirements, outlining battery chemistry, configuration, BMS (Battery Management System), and protective measures.

Technical Review: Present the proposed solution to the client, allowing for feedback and refinement.

Prototype Design Confirmation: Finalize the design blueprint, including detailed electrical, thermal, and mechanical aspects.

Technical Review: Present the proposed solution to the client, allowing for feedback and refinement.

Prototype Design Confirmation: Finalize the design blueprint, including detailed electrical, thermal, and mechanical aspects.

02

Prototype Development

Prototype Production: Assemble a sample battery pack based on the finalized design, integrating the selected battery cells, BMS, and casing.

Testing and Validation: Conduct performance testing, safety testing, and environmental testing to ensure the prototype meets the specified criteria.

Testing and Validation: Conduct performance testing, safety testing, and environmental testing to ensure the prototype meets the specified criteria.

03

Client Feedback and Adjustments

Prototype Review: Present the prototype to the client for functional evaluation and feedback.

Design Adjustments: Make necessary design modifications based on client feedback and additional testing results.

Design Adjustments: Make necessary design modifications based on client feedback and additional testing results.

04

Mass Production Preparation

Production Planning: Plan for large-scale production, including raw material procurement, manufacturing process setup, and quality control measures.

Final Testing: Perform a series of rigorous tests to ensure the battery packs meet safety and performance standards, as well as any regulatory requirements.

Final Testing: Perform a series of rigorous tests to ensure the battery packs meet safety and performance standards, as well as any regulatory requirements.

05

Mass Production

Batch Manufacturing: Initiate the large-scale production of the customized battery packs while maintaining strict quality control.

Quality Inspection: Perform continuous quality checks throughout the production process to ensure consistency and compliance with client specifications.

Quality Inspection: Perform continuous quality checks throughout the production process to ensure consistency and compliance with client specifications.

06

Delivery and After-Sales Support

Packaging and Delivery: Package the battery packs safely and arrange for timely delivery to the client.

Technical Support: Provide after-sales technical support, including installation guidance, usage training, and maintenance services.

Feedback Loop: Collect client feedback after deployment to improve future custom battery solutions.

Technical Support: Provide after-sales technical support, including installation guidance, usage training, and maintenance services.

Feedback Loop: Collect client feedback after deployment to improve future custom battery solutions.

07