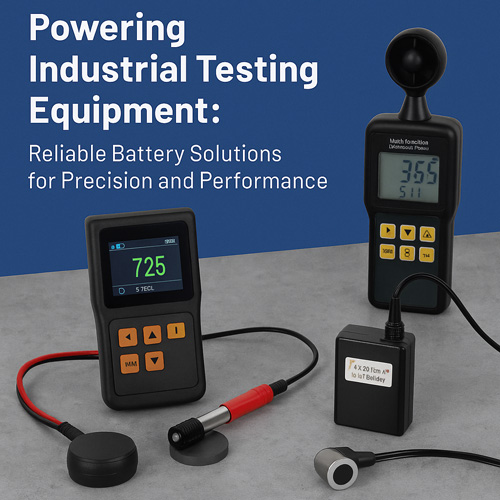

Reliable Battery Solutions for Ultrasonic Thickness Gauges

Stable, long-runtime lithium battery packs designed for industrial NDT inspection equipment

NDT Equipment Battery

Ultrasonic Thickness Gauge

Custom Li-ion Battery

Ultrasonic Thickness Gauge & Power Challenges

In the Non-Destructive Testing (NDT) industry, ultrasonic thickness gauges are essential tools for evaluating material thickness without causing damage. They are widely used in petrochemical pipelines, shipbuilding, aerospace structures, power facilities, and steel manufacturing.

However, the performance and accuracy of ultrasonic thickness gauges rely heavily on one core component — the battery system. An unstable or poorly designed battery can directly impact measurement reliability and on-site productivity.

Common Battery Pain Points in Ultrasonic Thickness Gauges

- Insufficient Runtime: Conventional disposable batteries often support only a few hours of operation, leading to frequent replacements and downtime.

- Poor Temperature Performance: Capacity drops significantly in cold outdoor environments or high-temperature industrial sites, causing unexpected shutdowns.

- Safety Risks: Leakage, swelling, or rising internal resistance may result in inaccurate readings or even damage the equipment.

- Maintenance & Logistics Issues: Disposable batteries increase procurement frequency, logistics cost, and environmental burden.

PKNERGY Battery Advantages for Ultrasonic Thickness Gauges

1. High Energy Density & Long Runtime

We offer high-performance lithium battery solutions using custom lithium polymer batteries and cylindrical Li-ion cells (18650 / 21700 / 26650). Single-cell capacities range from 1200mAh to 4800mAh, with configurable pack voltages such as 7.4V, 11.1V, and 14.8V.

Compared with conventional batteries, PKNERGY packs deliver up to 2–3× longer runtime.

2. Wide Temperature Performance

Our batteries are engineered for harsh environments, operating reliably from -30℃ to +60℃. Even in sub-zero conditions, they retain over 80% capacity, ensuring continuous field inspection.

3. Fully Customizable Battery Design

PKNERGY provides custom LiFePO4 battery and Li-ion pack designs tailored to your ultrasonic gauge housing:

- Built-in or replaceable battery structures

- Connectors: XT30, JST-PH, ZH, waterproof plugs

- Integrated PCM/BMS protection (overcharge, over-discharge, overcurrent, short-circuit, temperature)

4. Reliability & Certifications

All battery solutions comply with international standards including UN38.3, IEC62133, CE, RoHS, and MSDS. Our packs support over 1000 charge-discharge cycles and are safe for global transportation.

Typical Application Scenarios

- Petrochemical pipelines — corrosion inspection and safety monitoring

- Shipbuilding — steel plate thickness verification

- Aerospace — aircraft structure fatigue inspection

- Power plants — boiler and pressure vessel testing

- Metallurgy — high-temperature steel quality control

These applications often require reliable power under vibration, temperature fluctuations, and long inspection cycles — scenarios where PKNERGY batteries excel.

Why Choose PKNERGY for Ultrasonic Thickness Gauge Batteries?

PKNERGY is more than a battery supplier — we are a long-term energy solution partner for industrial inspection equipment manufacturers.

- Flexible MOQ: from prototypes to mass production

- Engineering support: structural design & rapid sampling

- Global experience: trusted by NDT equipment brands in Europe, North America, and Asia

We also support related industrial applications such as industrial automation battery solutions and portable detection device power solutions.

FAQ

Can PKNERGY customize batteries to match existing ultrasonic gauge housings?

Yes. We provide full customization including size, voltage, connector type, and internal protection design to fit your equipment precisely.

Are PKNERGY batteries suitable for outdoor and low-temperature inspections?

Absolutely. Our wide-temperature battery solutions are designed for stable operation in cold, hot, and harsh industrial environments.

Do your batteries support international shipping?

Yes. All battery packs meet UN38.3 and related transport certifications for safe global delivery.