Smart Prosthetic Battery Solutions: Powering the Future of Wearable Robotics with Custom Lithium Technology

High-density, medical-grade lithium packs engineered for intelligent prosthetic limbs and wearable robotics.

Introduction: Market Growth and the Power Behind Human Mobility

The future of prosthetics is intelligent, connected, and powered by innovation. Smart prosthetic limbs—featuring embedded sensors, motorized joints, AI-based control algorithms, and wireless connectivity—are transforming the lives of amputees by restoring motion with remarkable precision.

According to industry forecasts, the global prosthetics and orthotics market is projected to reach USD 2.5–3 billion by 2030, driven by rapid growth in powered and bionic prosthetic systems. Yet, despite advancements in biomechanics and neural interfaces, one challenge remains central: power supply performance.

A high-efficiency, lightweight, and safe battery system is the heart of every intelligent prosthetic limb. It dictates not only the duration of use but also how smoothly the limb moves, how fast it responds, and how safe it remains in continuous contact with the human body. This is where PKNERGY delivers unparalleled engineering expertise.

Market Demands and Key Technical Requirements

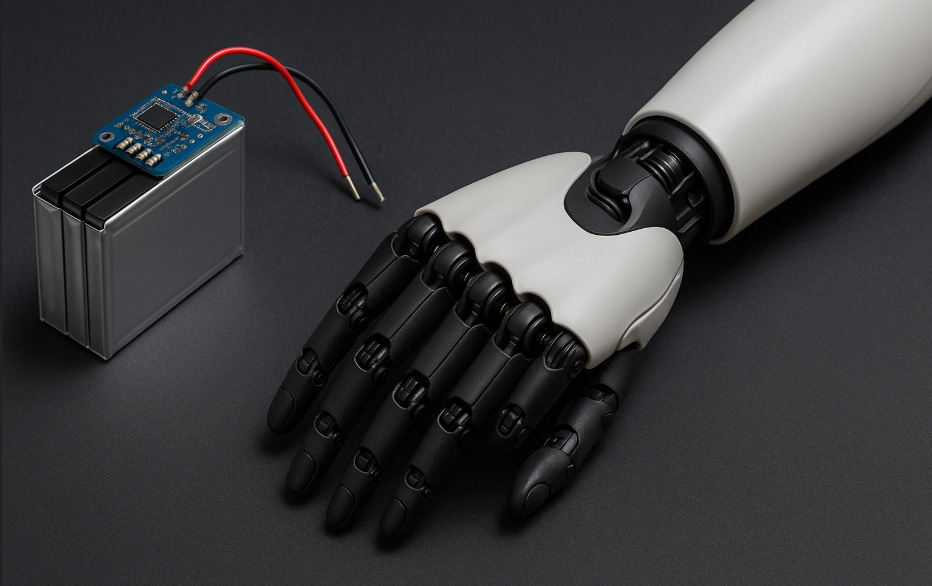

Unlike traditional passive prosthetics, smart limbs integrate multiple power-hungry components—actuators, microcontrollers, haptic feedback modules, and wireless data links. These devices require compact energy sources that balance endurance, safety, and performance.

Core Battery Requirements Include:

- ⚡ High Energy Density (150–250 Wh/kg): Maximizes operation time while minimizing weight.

- 🚀 High Discharge Capability: Supports fast, precise motor control and high current bursts (up to 20C).

- 💡 Compact & Flexible Design: Fits into curved or asymmetrical housing within the limb cavity.

- 🔋 Long Cycle Life (>800–1000 cycles): Ensures consistent reliability over years of daily usage.

- 🧠 Integrated BMS: Balancing, temperature control, and digital communication (CAN, RS-485, UART).

- 🩺 Medical-Grade Safety: Must meet UN38.3, IEC 62133, CE, UL, and ISO 13485 requirements.

For extra intrinsic safety in lower-limb devices, consider LiFePO₄ Battery chemistry; for compact, weight-critical upper-limb systems, a high-energy Li-ion pack may be preferable. When the mechanical envelope is complex, our Custom Pack service provides shape-tailored pouch solutions.

Typical Configurations

- Upper-limb prosthetics: 2S (7.4 V) or 3S (11.1 V) Li-Po packs, 800–2500 mAh, with 10C–20C continuous discharge.

- Lower-limb prosthetics / exoskeletons: 7S–8S (25.9 V–29.6 V) Li-ion packs, 3000–5000 mAh, with reinforced housings and BMS modules.

- Chemistry options: Li-ion (NMC, LCO) for high energy density, LiFePO₄ for enhanced safety, and Li-Po pouch cells for design flexibility.

PKNERGY’s Engineering Excellence and Customization Capability

At PKNERGY, we don’t believe in “one-size-fits-all.” Every prosthetic system has unique voltage, size, and performance constraints—so we engineer every battery from the cell level up.

🔋 Custom Cell Configuration

From compact 2S packs to high-voltage multi-series assemblies, tailored to your mechanical and electrical requirements. See our Custom Pack service.

🧠 Smart BMS Design

Custom PCBs with active balancing, short-circuit prevention, and multi-channel communication options (CAN, RS-485, SMBus).

🧩 Precision Mechanical Integration

Slim pouch cells, flexible shapes, IP-rated enclosures, and anti-vibration mounts designed to fit inside prosthetic shells.

🧪 Testing & Validation

Drop, vibration, temperature, and overcurrent testing, simulating real prosthetic motion cycles.

🌍 Global Certification Support

Assistance with UN38.3, IEC 62133, CE, UL, RoHS, and ISO 13485 for medical-grade devices.

⚙️ Turnkey Solutions

From cell selection, pack design, and firmware tuning to charger customization and pilot-run validation.

Case Insight: Optimizing Power for Smart Prosthetics

A typical myoelectric prosthetic arm employs a 3S (11.1 V) Li-Po 1500 mAh pack with 20C discharge capability, delivering up to 30 A peak current for multiple servo motors. With optimized BMS design and active thermal monitoring, PKNERGY ensures stable operation and smooth actuation.

For powered lower-limb prosthetics or robotic exoskeletons, our engineers recommend an 8S (29.6 V) 4000 mAh Li-ion configuration, paired with a high-speed CAN-enabled BMS. This setup provides superior torque response and over 6 hours of continuous operation per charge, while maintaining total system weight under 1.2 kg.

Engineering Insight: Why Li-Po and Li-ion Are Ideal for Prosthetics

- Li-ion (NMC, LCO): Exceptional energy density and compactness, ideal for high-end prosthetic arms.

- LiFePO₄: Thermal stability and long cycle life—suitable for safety-critical lower-limb or rehabilitation devices. Learn more about our LiFePO₄ Battery.

- Li-Po pouch cells: The most flexible option for customized shapes and weight-sensitive applications.

By combining these chemistries with PKNERGY’s proprietary cell matching and pack balancing algorithms, we deliver high-efficiency battery modules that sustain consistent performance over hundreds of cycles.

Chemistry Comparison Table

| Parameter | Li-ion (NMC/LCO) | Li-Po (Pouch) | LiFePO₄ |

|---|---|---|---|

| Energy Density | High (180–250 Wh/kg) | High (170–230 Wh/kg) | Moderate (120–160 Wh/kg) |

| Safety / Thermal Stability | Good with robust BMS | Good with robust BMS | Excellent, inherently stable |

| Cycle Life | 800–1000+ | 800–1000+ | 1500–3000+ |

| Discharge Capability | Up to 15–20C | Up to 20C+ | 10–15C (typ.) |

| Form Factor Flexibility | Moderate | Excellent (thin, curved) | Moderate |

| Best Use Case | Upper-limb, compact high energy | Upper-limb, shape-critical designs | Lower-limb, safety-critical systems |

Explore: LiFePO₄ Battery · Custom Pack

Why Manufacturers Choose PKNERGY

- ✅ Tailor-made designs that perfectly match each device’s electrical and structural layout.

- ✅ End-to-end support, from concept and prototyping to production and compliance.

- ✅ Proven reliability, through advanced quality control, traceability, and automated testing.

- ✅ Medical-grade quality assurance, meeting ISO 13485 and IEC 62133 standards.

- ✅ Rapid delivery and technical partnership, shortening your R&D cycle and speeding your time-to-market.

Ready to build the next generation of smart prosthetics? Our Custom Pack team can co-design with your mechanical and control engineers to optimize weight, runtime, and responsiveness.

FAQ

What battery chemistry should I choose for upper-limb vs. lower-limb prosthetics?

Upper-limb systems usually favor Li-ion or Li-Po for higher energy density and compactness. Lower-limb and safety-critical systems often prefer LiFePO₄ for superior thermal stability and longer cycle life.

How many hours of runtime can I expect?

Runtime depends on actuator duty cycle, average current, and pack capacity. As a guide, an 8S 4000 mAh Li-ion pack with CAN-enabled BMS can sustain >6 hours in many lower-limb applications under typical gait profiles.

Do you support medical certifications?

Yes. We support UN38.3, IEC 62133, CE, UL, RoHS, and ISO 13485. Our documentation package accelerates device compliance and market entry.

Can you design custom shapes to fit tight enclosures?

Absolutely. Our Custom Pack service leverages slim pouch cells, curved profiles, and IP-rated housings to match your mechanical envelope.

What communication interfaces are available?

CAN, RS-485, UART, and SMBus are available with options for active balancing, short-circuit protection, and thermal monitoring.

Contact Miah — PKNERGY

Let’s collaborate to design a custom lithium battery solution that makes your prosthetic product safer, lighter, and smarter.

- 📧 Email: sale@pknergy.com

- 📱 Phone / WhatsApp: +86 139 0246 3897

- 🌐 Website: pknergy.com | pknergybattery.com